In the age of COVID-19, more and more people are turning to UV-C light as a means to disinfect everything from surfaces to surgical instruments. As we've highlighted in other blogs, UV-C light provides a great method of disinfection against infectious diseases and viruses, without the drawbacks and after effects that accompany chemical disinfectants and fogs.

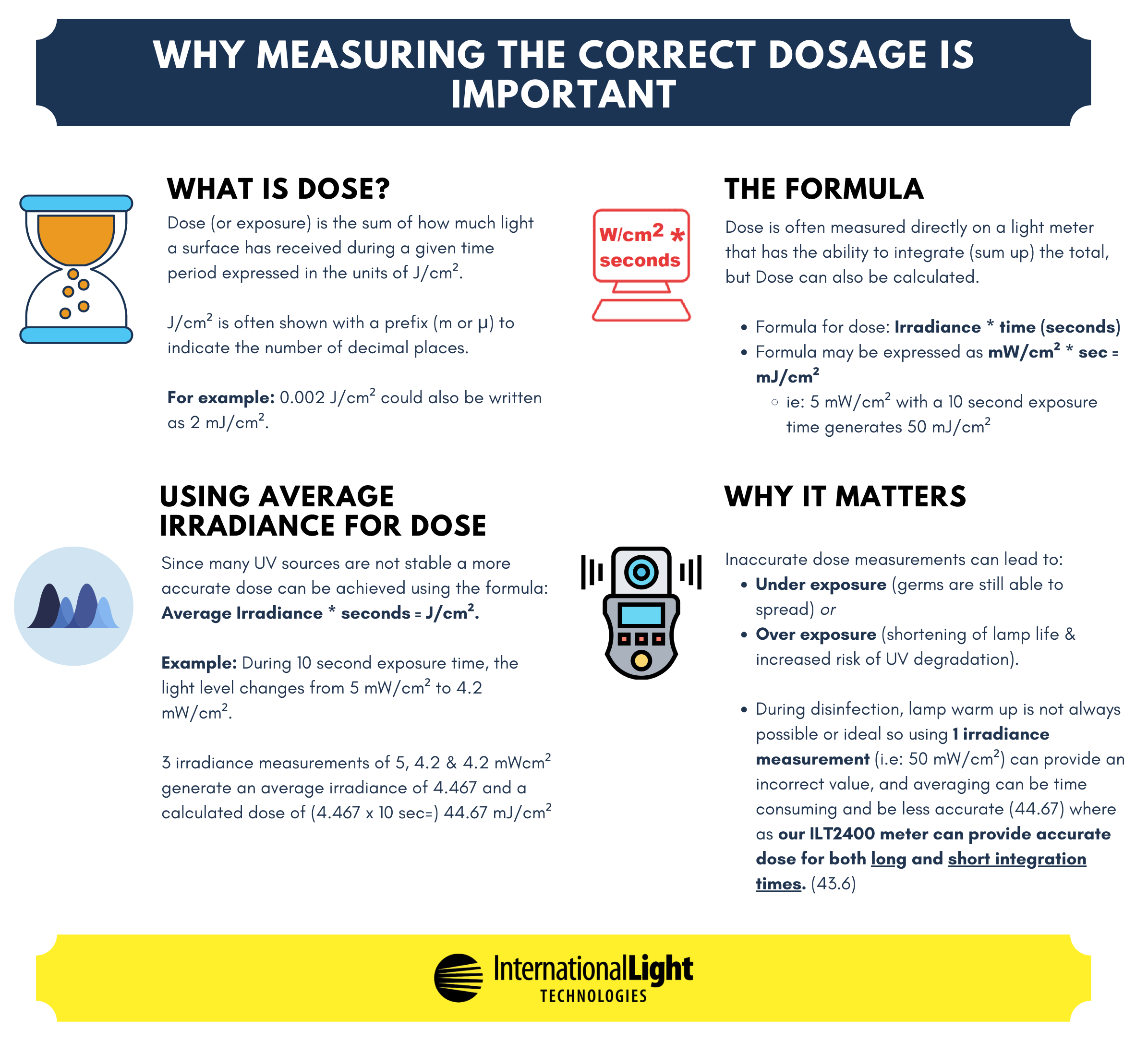

When using UV-C light for disinfection, it's important that the proper amount - or dose - of light is applied in order to effectively irradiate the target. Every microbe has a calculated dose for deactivation. This calculated dose is seen as a formula where dose is the product of irradiance and exposure time.

Verifying the actual amount of light reaching a surface is a critical step in the disinfection process, as many factors can impact this. In order to get an accurate measurement, a light meter that will integrate multiple measurements over the exposure time must be used.

The below graphic offers an easy-to-understand visual on why measuring dose, and not just calculating it, is important.

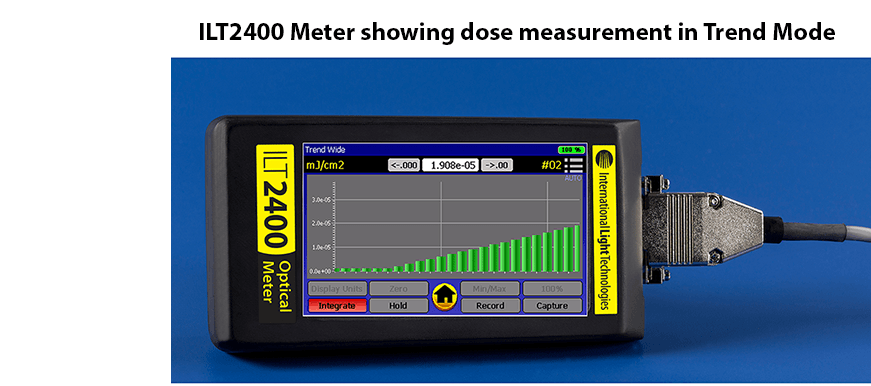

ILT UVGI light meters have the ability to measure, graph and record the dose during the UV disinfection processes. Our meters can be configured with sensors for UVC covering a range of 185 to 280nm as well as broadband UV sensors covering UV, and VIS. ILT light meters can measure at speeds of up to 20 uSec for pulsed light sources as well as for accurately tracking changes intensity over time to assure accurate dose measurements.

Shop Our Complete Line Of Configured UV-C Light Measurement Systems >>