What is an ISO17025 accredited and NIST traceable calibration and why is it important?

Most light meters read out in empirical units such as lux, foot candles, watts per square centimeter, watts, etc. But not all systems that read out in the same units have the same quality of calibration behind the values.

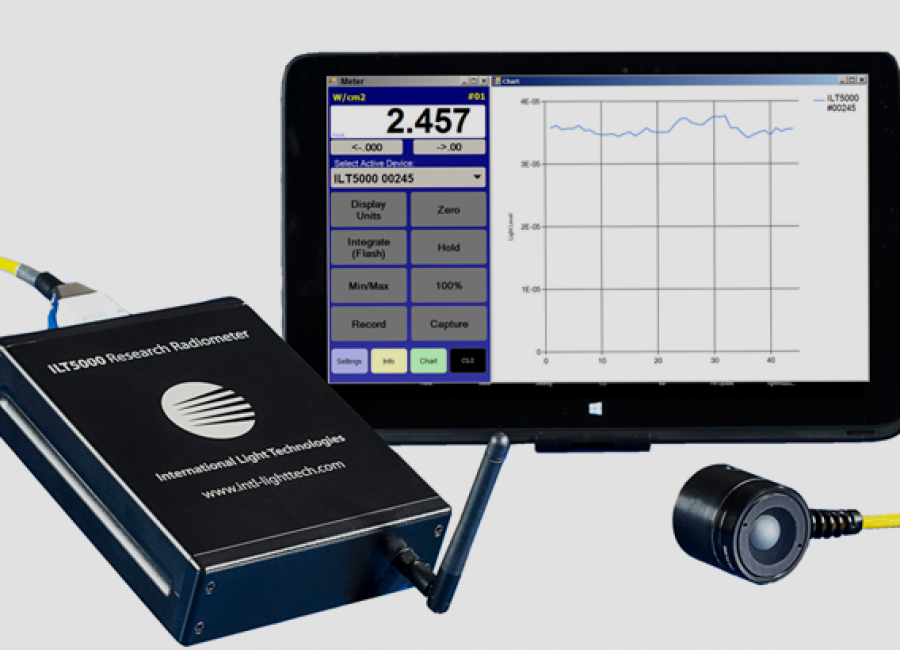

To start, most light measurement systems include a sensor that, when exposed to light, generates current or voltage proportional to the amount of light received. The light meter takes the incoming signal and converts it to a light-level reading in the appropriate units. This is usually accomplished by applying a calibration factor.

It is a combination of the quality of the components, and the quality of the calibration that ensures the conversion from volts or amps to the light level reading is accurate. Without accurate calibration the readout is simply a relative value, and the units on the meter may as well list volts, amps, relative, or percent. Accurate, accredited, traceable calibration means the readings on the display have value. They can be trusted.

But do you really need NIST and ISO?

NIST traceable calibrations requires that the sensors used to create the calibration be traced back to a sensor that was calibrated at the NIST calibration lab. However most labs do not use the actual sensor from NIST to perform calibrations. Instead, they use this as a 'golden standard' or the validation system. From the golden standard, working standards are created. The working standards are then used by the primary calibration lab to perform calibrations of sensors in the lab. Often these sensors are then used by other labs to perform calibrations and/or create additional working standards. Each transfer of the calibration increases the level of the calibration uncertainty. It is not possible for the working standard to have the same calibration uncertainty as the sensor directly calibrated at NIST. This means that even with a NIST traceable sensor, it is often important to understand how far removed the sensor is from the actual calibration at NIST. It is also important to verify the chain between NIST and the users device is not broken, and that each transfer applies to the correct, higher uncertainty value.

ISO/IEC 17025:2017 does not provide standards for performing calibrations. It takes the NIST traceability up to a higher level of quality and assurance. Cal labs with ISO/IEC 17025:2017 accreditation are required to verify the uncertainties, review all policies and procedures in a timely manner, perform in-house as well as outsourced QC checks of all systems in the lab, and continuously work to improve their processes and procedures. Calibrations must be performed by multiple personnel at different time periods to ensure the uncertainties noted are valid, not assumed, or copied from other suppliers' cal certs. ISO/IEC 17025:2017 accreditation requires the lab to be evaluated every year, and to maintain and publish their scope of calibration capabilities. ISO is all about quality and improvements.

When combining NIST traceability with ISO/IEC 17025:2017 accreditation, the customer is assured the highest quality for their calibrations. Since NIST traceability can be transferred an innumerable amount of levels as long as the chain is properly noted, NIST traceability alone does not guarantee excellence of calibration. It is the combination of traceability and quality assurance, that ensures the highest standards.

For the end customer this means they can rely on their light measurement system to provide accurate readings in the appropriate units.

ILT was founded in 1965 and has been manufacturing light meters for over 50 years. We have been offering NIST traceable calibrations for over 40 years. In 2012 our lab became ISO/IEC 17025:2017 accredited. ILT maintains a vast system of working standards, and our database of calibration records date back more than 25 years. This enables us to notify our customers when system calibration is due, provide them an accurate history of their service, support them during a calibration audit, and show trends in system performance.